Zatražite ponudu.

Turn wastewater into pure water with our AxoPur system

The AxoPur system offers a compact, one-step solution for converting contaminated wastewater into clean water. elektrokoagulaciju za učinkovitu obradu različitih vrsta otpadnih voda, uključujući industrijske otpadne vode, komunalne otpadne vode, procjedne vode s odlagališta i oborinske vode. Ovaj postupak učinkovito uklanja suspendirane čestice, emulgirana ulja, metale, fosfor i mikroorganizme.

Sustav koristi električnu energiju za pročišćavanje, omogućujući preciznu kontrolu procesa i fino podešavanje putem mjerenja vodljivosti (feed-forward) ili mutnoće (feed-back) u stvarnom vremenu. Pročišćavanje se odvija trenutno, a sustav je dizajniran za kontinuirani rad. Može upravljati varijabilnim ili povremenim protokom pomoću bafera ili kontrole razine u spremniku, omogućujući automatsko pokretanje i zaustavljanje prema potrebi.

Ovaj sustav proizvodi visok udio pročišćene vode, često zamjenjujući ili dopunjujući kupljenu svježu vodu, čime smanjuje volumen otpadnih voda i potrošnju svježe vode, značajno smanjujući rizik od nestašice vodnih resursa.

Fleksibilno upravljanje prostorom i protokom

AxoPur systems offer versatile solutions for wastewater treatment across various industries, including professional vehicle washing, pulp and paper, prehrambenu industriju, proizvodnja mliječnih proizvoda, fish farming, and aquaculture. Depending on space availability and flow requirements, AxoPur systems can be deployed in either skid-mounted or containerized configurations.

Containerized solutions

A containerized AxoPur system integrates all process equipment within one or two insulated containers, featuring standardized external connections and a temperature control system to maintain optimal operating conditions. This compact design minimizes the footprint, making it an excellent choice for space-constrained applications.

Containerized AxoPur systems are particularly beneficial for mobile and time-limited wastewater purification projects or situations where indoor space is unavailable. They provide an efficient and scalable solution, supporting continuous operation with flow rates from 1 to 40 m³/h in standardized containers.

Skid-mounted solutions

A skid-mounted AxoPur system is ideal for installations within existing buildings where space allows for flexible layout arrangements. The process equipment is mounted on a couple of skids that can be positioned along walls or placed freely, enabling efficient use of available space. These systems handle flows ranging from 1 to 40 m³/h, providing an effective and compact wastewater treatment solution for diverse industrial applications.

For higher flow rates exceeding 40 m³/h, the AxoPlus system is recommended. This high-capacity solution is customized to meet specific requirements and is available in both skid-mounted and containerized configurations.

Pilot projekt

Pilot projekte provode iskusni inženjeri Mellifiqa, omogućujući preciznu prilagodbu od pilot razine do punog kapaciteta. Nudimo pilot projekte na lokaciji klijenta, kao i interno testiranje u malim razmjerima, ovisno o veličini projekta.

Saznajte više o našim pilot projektima ovdje.

AxoPur A-series

AxoPur A-serija je standardizirani kontejnerski sustav smješten u 10’ kontejner, koji koristi 1–3 AxoPur reaktora, svaki s hidrauličkim kapacitetom od 3 m³/h. To omogućuje sustavu kontinuirani rad s protocima od 1 do 6 m³/h. Za odvajanje zagađivača, dostupan je dodatni 20’ kontejner s flotacijskom jedinicom.

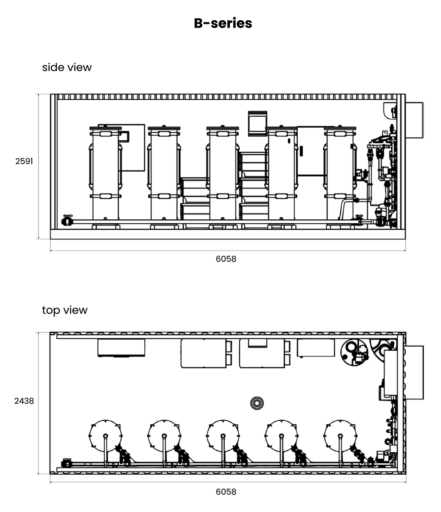

AxoPur B-series

AxoPur A-serija je standardizirani kontejnerski sustav smješten u 10’ kontejner, koji koristi 1–5 AxoPur reaktora, svaki s hidrauličkim kapacitetom od 3 m³/h. To omogućuje sustavu kontinuirani rad s protocima od 3 do 20 m³/h. Za odvajanje zagađivača, dostupan je dodatni 20’ kontejner s flotacijskom jedinicom.

Technical data AxoPur®

| AxoPur® | A serija | B serija | Preuzimanja | ||||||

| Modeli | A1 | A2 | A3 | B1 | B2 | B3 | B4 | B5 | Tehnička list |

| Nominal flow rate (m3/h) | 3 | 6 | 9 | 5 | 10 | 15 | 20 | 25 | |

| Number of reactors | 1 | 2 | 3 | 1 | 2 | 3 | 4 | 5 | |

| Pipe connection | 4 x DN 32 flanges | 4 x DN 50 flanges | |||||||

| Power connection | 3-phase 400 V | ||||||||

| Reactor material | Polypropylene | ||||||||

| Piping material | PVC-U PN10 | ||||||||

| Electrode | Iron or Aluminum | ||||||||

| Automatizacija | 7” control panel with reactor current controls and MODBUS TCP | ||||||||

| Input power (kW) | 1.5 | 3 | 4.5 | 2.5 | 5 | 7.5 | 10 | 12.5 | |

| Dosing station for polymer | Included | Included | |||||||

| Footprint (containerized) | 2,990 x 2,590 x 2,438 | 6,058 x 2,591 x 2,438 | |||||||

| Footprint (skid-mounted) | 2,800 x 2,600 x 2,600 incl. service space | 5,800 x 2,600 x 2,400 incl. service space | |||||||

*Nominal water conditions conductivity 1.5 mS/cm, pH 5 – 9.5, at design temperature 5-40 deg C, pH 7.2, COD 250 mg/l, phosphorus 4 mg/l, heavy metals<50 mg/l, oil index 10 mg/l and TSS 100 mg/L. All performance data is subject to 15% performance tolerances and the end user is fully responsible for itscorrectness pertaining to actual feed water quality.

Powerful treatment in a compact package – Discover the benefits of the AxoPur system here.

Seamless intergration with other systems

The AxoPur® system is designed for seamless integration with a wide range of products and systems from our other brands. It is effectively combined with Water Maid™ filtration and adsorption systems, as well as with the Water Maid™ dosing stations and OptiFloc™ flotation units, ensuring optimal removal of contaminants. Furthermore, AxoPur® is compatible with Ozonetech’s RENA Vivo ozone systems, enabling advanced oxidation processes for enhancing water quality and disinfection. By combining these technologies, we offer flexible, high-performance solutions tailored to meet the complex demands of various industries.

Accessories and Scope

| Pribor | Scope |

| Stanica za doziranje pH | Optional including automatic pH control PLC |

| CIP stanica | Opcionalni dodaci |

| Rinse connections | Included |

| Heating | Optional with containerization |

| Senzori | ORP, conductivity and additional pH sensors optional |

| Feed water buffer tank | 150 and 300 L tank optional |

| Floc flotation unit | Included in OptiFloc™ polishing system |

| Polymer dosing station | Included in OptiFloc™ polishing system |

| Sludge collection unit | Included in OptiFloc™ polishing system |

| Sludge dewatering unit | Included in OptiFloc™ polishing system |

Povezani referentni projekt.

Mellifiq solves enduring groundwater problem with our AquaFloc

Unique micropollutant solution at wastewater treatment plant