Request a quote.

Turn wastewater into pure water with our AxoPur system

The AxoPur system offers a compact, one-step solution for converting contaminated wastewater into clean water. Electrocoagulation is utilized to effectively treat different types of wastewater, such as industrial effluents, municipal sewage, landfill leachate, and stormwater. This process efficiently eliminates suspended solids, emulsified oils, metals, phosphorus, and microorganisms.

The AxoPur system uses electricity for purification, offering efficient process control and fine-tuning options, such as inline measurement of feed-forward conductivity or feed-back turbidity. The purification occurs instantly, and the system is designed for continuous operation. It can also manage variable or intermittent flows through a buffer volume and/or level control in a tank, allowing for automatic start and stop when needed.

The system produces a high yield of purified water, often replacing or supplementing purchased fresh water. This reduces both effluent and fresh water volumes, significantly lowering the risk of fresh water supply shortages.

Flexible Space and Flow Management

AxoPur systems offer versatile solutions for wastewater treatment across various industries, including professional vehicle washing, pulp and paper, food processing, dairy production, fish farming, and aquaculture. Depending on space availability and flow requirements, AxoPur systems can be deployed in either skid-mounted or containerized configurations.

Containerized Solutions

A containerized AxoPur system integrates all process equipment within one or two insulated containers, featuring standardized external connections and a temperature control system to maintain optimal operating conditions. This compact design minimizes the footprint, making it an excellent choice for space-constrained applications.

Containerized AxoPur systems are particularly beneficial for mobile and time-limited wastewater purification projects or situations where indoor space is unavailable. They provide an efficient and scalable solution, supporting continuous operation with flow rates from 1 to 40 m³/h in standardized containers.

Skid-Mounted Solutions

A skid-mounted AxoPur system is ideal for installations within existing buildings where space allows for flexible layout arrangements. The process equipment is mounted on a couple of skids that can be positioned along walls or placed freely, enabling efficient use of available space. These systems handle flows ranging from 1 to 40 m³/h, providing an effective and compact wastewater treatment solution for diverse industrial applications.

For higher flow rates exceeding 40 m³/h, the AxoPlus system is recommended. This high-capacity solution is customized to meet specific requirements and is available in both skid-mounted and containerized configurations.

Pilot project

Pilot projects can be conducted by Mellifiq’s experienced engineers, which allows for high resolution scaling from pilot levels to full scale installation. We offer both on-site pilot projects aswell as in-house small scale pilots depending on project size.

Read more about our pilot projects here.

AxoPur A-series

The AxoPur A-series is a standardized containerized system in a 10’ container making use of 1–3 AxoPur reactors with a hydraulic capacity of 3 m³/h each, giving the system as such an operational coverage range from 1–6 m³/h at continuous operation. For the separation of the contaminants a separate 20’ container including a flotation unit is available.

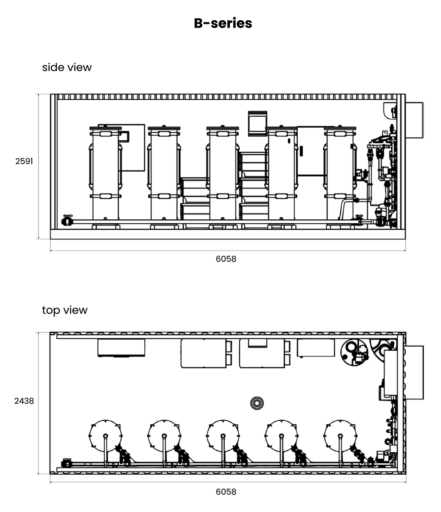

AxoPur B-series

The AxoPur B-series is a standardized containerized system in a 20’ container making use of 1–4 AxoPur reactors with a hydraulic capacity of 5 m³/h each, giving the system as such an operational coverage range from 3–20 m³/h at continuous operation. For the separation of the contaminants a separate 20’ container including a flotation unit is available.

Technical data AxoPur®

| AxoPur® | A-series | B-series | Downloads | ||||||

| Model | A1 | A2 | A3 | B1 | B2 | B3 | B4 | B5 | Datasheet |

| Nominal flow rate (m3/h) | 3 | 6 | 9 | 5 | 10 | 15 | 20 | 25 | |

| Number of reactors | 1 | 2 | 3 | 1 | 2 | 3 | 4 | 5 | |

| Pipe connection | 4 x DN 32 flanges | 4 x DN 50 flanges | |||||||

| Power connection | 3-phase 400 V | ||||||||

| Reactor material | Polypropylene | ||||||||

| Piping material | PVC-U PN10 | ||||||||

| Electrode | Iron or Aluminum | ||||||||

| Automation | 7” control panel with reactor current controls and MODBUS TCP | ||||||||

| Input power (kW) | 1.5 | 3 | 4.5 | 2.5 | 5 | 7.5 | 10 | 12.5 | |

| Dosing station for polymer | Included | Included | |||||||

| Footprint (containerized) | 2,990 x 2,590 x 2,438 | 6,058 x 2,591 x 2,438 | |||||||

| Footprint (skid-mounted) | 2,800 x 2,600 x 2,600 incl. service space | 5,800 x 2,600 x 2,400 incl. service space | |||||||

*Nominal water conditions conductivity 1.5 mS/cm, pH 5 – 9.5, at design temperature 5-40 deg C, pH 7.2, COD 250 mg/l, phosphorus 4 mg/l, heavy metals<50 mg/l, oil index 10 mg/l and TSS 100 mg/L. All performance data is subject to 15% performance tolerances and the end user is fully responsible for itscorrectness pertaining to actual feed water quality.

Powerful treatment in a compact package – Discover the benefits of the AxoPur system here.

Seamless intergration with other systems

The AxoPur® system is designed for seamless integration with a wide range of products and systems from our other brands. It is effectively combined with Water Maid™ filtration and adsorption systems, as well as with the WaterMaid™ dosing stations and OptiFloc™ flotation units, ensuring optimal removal of contaminants. Furthermore, AxoPur® is compatible with Ozonetech’s RENA Vivo ozone systems, enabling advanced oxidation processes for enhancing water quality and disinfection. By combining these technologies, we offer flexible, high-performance solutions tailored to meet the complex demands of various industries.

Accessories and Scope

| Accessories | Scope |

| pH dosing station | Optional including automatic pH control PLC |

| CIP station | Optional |

| Rinse connections | Included |

| Heating | Optional with containerization |

| Sensors | ORP, conductivity and additional pH sensors optional |

| Feed water buffer tank | 150 and 300 L tank optional |

| Floc flotation unit | Included in OptiFloc™ polishing system |

| Polymer dosing station | Included in OptiFloc™ polishing system |

| Sludge collection unit | Included in OptiFloc™ polishing system |

| Sludge dewatering unit | Included in OptiFloc™ polishing system |

Related reference project.

Mellifiq solves enduring groundwater problem with our AquaFloc

Unique micropollutant solution at wastewater treatment plant