Request a quote.

A Filtration Technology With Unmatched Efficiency and Durability

The HydraLuxe membrane offers a cutting-edge solution for water and wastewater treatment, delivering high performance with reduced operational complexity. Its high flux rate minimizes footprint, energy, and chemical consumption, while its chemically inert design ensures long-term resistance with no permeability decline. A negatively charged surface reduces fouling from organics and oil, and its extreme durability makes cleaning effortless. With the ability to handle high solids loading—from a few ppm to several % TSS—the HydraLuxe membrane simplifies treatment by integrating filtration, sedimentation, flotation, and absorption into a single process step. This results in a smaller footprint, lower costs, and greater efficiency, making it the ideal choice for advanced water treatment solutions.

Versatile Applications Across Industries

The HydraLuxe membrane technology is designed for a wide range of water and wastewater treatment applications. It is ideal for drinking water purification, sand filter rehabilitation, and filter backwash recovery, as well as PFAS and micropollutant removal from surface and seawater. It effectively treats groundwater (both sweet and brackish), industrial wastewater, scrubber water, and coal chemical effluents. Key industries benefiting from this technology include food & beverage, petrochemicals, mining, and municipal wastewater management. Additionally, it enhances MBR sludge thickening, treated sewage effluent (TSE) processing, and stormwater overflow management, offering a highly efficient and adaptable filtration solution.

Technology Overview

The HydraLuxe is a cutting-edge solid-liquid separation technology designed for superior water purification. This advanced membrane system effectively removes a wide range of contaminants, including:

- Suspended solids & turbidity – Ensuring crystal-clear water

- Bacteria, viruses & algae – Providing microbiological safety

- PFAS/PFOS & micropollutants – Excellent pre-treatment method for PFAS and PFOS

- Oil & heavy metals – Enhancing industrial and environmental safety

- Suspend substances – Achieving ultra-pure results with integrated adsorption and coagulation

Engineered for reliability and efficiency, the HydraLuxe delivers high-performance filtration for industrial, municipal, and environmental applications.

Operational Capabilities

A HydraLuxe membrane and module is highly durable and hence able to effectively treat wide range of water sources.

| Operational Capabilities | |||||||

| Solids loading tolerance (TSS) | 1 ppm – 50.000 ppm | ||||||

| Temperature | 2-60 °C | ||||||

| Abrasive media in feed water | No Limitations | ||||||

| Chemical tolerance | pH 2-12 | ||||||

| Fat, Oil & Grease tolerance | Up to 400 ppm | ||||||

| Intermittent operation & dry storage | Allowed | ||||||

| Operational flux rate | 1-1000 LMH | ||||||

Filtration Principle and How It Works

The filtration sheet is submerged outside in, where clean water is drawn through the membrane with suction pressure. Suspended solids and bacteria are rejected on the membrane surface forming a cake layer while clean water is passing through the membrane body and is collected at both end caps.

The permeate water from each of the 42 membrane sheets is collected inside both ends of the membrane module permeate lines and finally runs through the top permeate module manifold. During backwash, the flow rate is reversed to push off the solids build up on the membrane surface

Self-Cleaning Feature

The top permeate module comes with an integrated sprinkler system. Two pipes with an engineered hole pattern, provides an even water jet distribution over the membrane modules. The sprinkler system serves two main purposes:

1. After the membrane tank is drained, spray permeate-, tap- or service water to mechanically remove debris and sludge trapped between the membranes.

2. Chemical spray cleaning over the membranes. The capillary forces of the membrane will absorb the chemical solution and clean the membranes where it is needed. This has the following advantages:

a) Replaces conventional CIP cleaning

b) Reduces chemical consumption by 95% compared to conventional CIP (Clean-in-place)

c) Keeps chemicals on the feeding side so it doesn’t come into contact with permeate line.

Module Towers and Racks

The membrane sheets are fitted in a square module consisting of 42 membrane sheets that are individually interchangeable. The modules are submersible and can be stacked individually on top of each other up to 15 modules in total. The membrane surface area is the determining factor for the capacity of the installation, the more surface area the more flow through the plant. Filtered water from each single plate is collected inside the module housing and transported to the top header integrated in both module housing sides.

Membrane Specification Table

| Classification | |

| Item code | HydraLuxe |

| Membrane type | Submerged Flat sheet |

| Operation mode | Out-to-in filtration |

| Pore size | 0.1 µm |

| Clean water permeability | > 3.000 LMH/bar @20 °C |

| Certification | NSF61 HOT (60 °C) |

| Material | |

| Membrane material | Silicon Carbide (SiC) ceramic |

| End-cap material | PPS 40% Glass fill |

| O-ring | EPDM (Viton or NBR on demand) |

| Potting material | PU |

| Dimensions | |

| Membrane surface area | 0.164 m2 |

| Length | 575 mm |

| Width | 145 / 154 mm |

| Thickness | 6 / 11 mm |

| Weight | 0.9 kg |

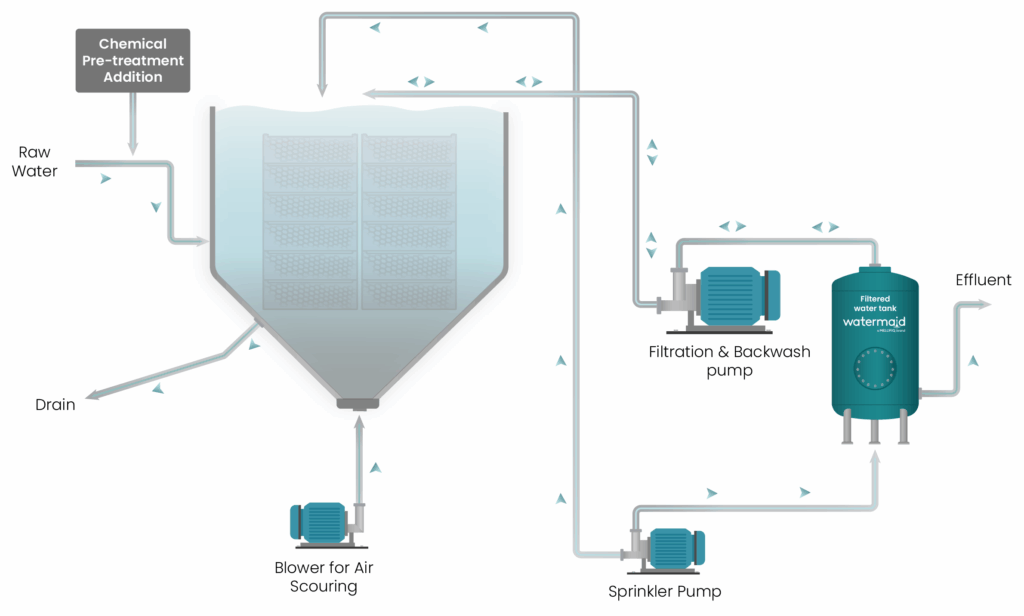

Process Flow Sheet

The versatility of HydraLuxe membrane technology enables a wide range of use cases and allows users to combine multiple process steps into a single operation:

- Membrane filtration

- Sedimentation

- Flotation

- Adsorption

This integrated approach allows for the removal of not only suspended solids and bacteria, but also PFAS, dissolved organics, heavy metals, and radioactive isotopes — all in a single filtration step.

Module and Tower Specification Table

| Specification | Downloads | |

| Item code | HydraLuxe membrane | Datasheets |

| Number of flat sheet membranes pr. module | 42 pcs | |

| Active membrane surface pr. module | 6.9 m2 | |

| Module material | PPO/PS GF | |

| Piping material | PP | |

| Clean water permeability | > 3.000 LMH/bar | |

| Maximum suction pressure | -0.7 bar | |

| Maximum backwash pressure | 1.2 bar | |

| Certification | NSF61 HOT (60 °C) | |

| Dimensions and connections | ||

| Internal aeration pipe dimensions | OD32 / ID28 mm | |

| Sprinkler pipe dimensions | OD40 mm | |

| Top permeate module dimensions | L 700 x W 570 x H 250 mm | |

| Permeate manifold dimensions | OD110 / ID90 mm | |

| Membrane module dimensions | L 700 x W 570 x H 160 mm | |

| Base module dimensions | L 700 x W 570 x H 260 mm | |

| Allowable stacking height | 1-15 modules | |

| Air-scouring connection | 2 x R1 1/4″ Thread | |

| Sprinkler pipe connection | R1 1/4″ Thread | |

| Bottom permeate connection | 1 ½” thread BSP | |

| Top permeate connection | Flange DN100 (ISO 7005 PN10) | |

| Dimensions | ||

| Dry weight Top-/Filter-/Base module | 10/44/9 kg | |

| Wet weight Top-/Filter-/Base module | 11/56 /9 kg | |

| Displacement volume Top-/Filter-/Base module | 8/16/7 l | |

Related reference project.

Mellifiq solves enduring groundwater problem with our AquaFloc

Unique micropollutant solution at wastewater treatment plant